BMBF approves neutron-research novelty POWTEX

In order to provide the large chemistry and materials-science communities with a powerful tool for rapid data acquisition, a time-of-flight diffractometer to be installed at the new Munich reactor has been designed between 2003 and 2006 and approved by BMBF in 2007. The time-of-flight technique is expected to outperform a monochromator instrument by one order of magnitude in intensity on particularily small samples of less than a cubic centimeter. The construction of this innovative type of diffractometer utilizes modern neutron components such as focusing super-mirror neutron guides, a four-unit high-speed disk-chopper system and linear position-sensitive detectors covering a solid angle of about 3 steradian. The diffractometer design enables an easy enlargement of the focal spot size and is therefore equally well suited for the texture analysis of large geological and archeological samples.

Fundamental objectives of solid-state chemistry and materials science are the development of new materials, their analytical characterizations and studies of their structures and properties. For that purpose, preparative methods have to be directly related to structure determination, since this is a prerequisite for designing materials of specific properties. Demands of solid-state chemists for a neutron diffractometer are a suitable d-spacing resolution, a d-spacing range of about 0.5 Å to 15 Å and high intensity on small samples. Even more important is a short-term access to the instrument without a lengthy proposal system and local services for both experiment and data analysis. The material and not the experiment is always the focus of the interest.

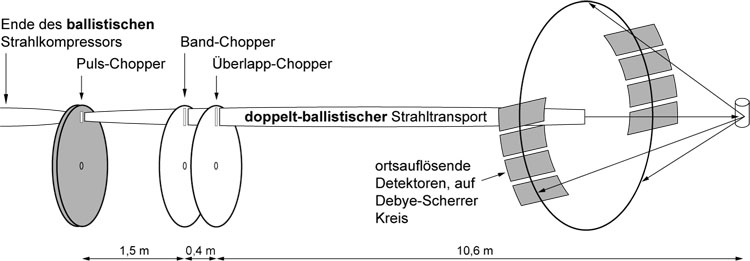

The proposed time-of-flight diffractometer POWTEX is designed for high intensity even with very small samples at a reasonably good resolution of d-spacings. Applying modern technologies like super-mirror guides, high-speed disk choppers with magnetic bearings and linear position-sensitive 3He detectors, an instrument can be designed so as to reach these goals. A schematic representation of the instrument is shown in the following sketch:

Neutrons from the beam channel SR5 of the FRM-2 are focused onto the slits of a pulse-defining double-disk chopper by a 25 m long "ballistic" beam compressor made of m = 3 super-mirror guides, i.e., guides with three times the critical glancing angle of nickel-coated guides. The beam is then defocused horizontally and focused vertically so as to form a specific exit cross section after a flight path of 11.85 m. In order to prevent direct sight onto the heavy-water reflector of the reactor, which minimizes fast neutron background, the guide to the pulse chopper will be mounted at a certain angle to the beam center line. The other two choppers are needed to define both the position of the wavelength band, which will be accessible and to prevent cross talk of consecutive pulses. The most important features of the instrument are high intensity by exploiting a large fraction of the Debye-Scherrer rings, variable d-spacing and resolution ranges, no limitations in determining peak positions (using position sensitive detectors without collimators) and unrestricted utilization as both a powder and a texture diffractometer.

Analytical performance estimates have shown that the neutron current at the sample position will be approximately equal for both a monochromator and a time-of-flight diffractometer. However, the absence of the resolution asymmetry of the time-of-flight method will result in an intensity gain for detected neutrons of about an order of magnitude with an initial detector arrangement covering a solid angle of 3.1 radian. The optimization of the numerous components of the instrument can be better followed up quantitatively with modern Monte Carlo techniques such as the VITESS code developed at the HMI. These simulations show that the proposed time-of-flight diffractometer outperforms a conventional monochromator instrument by about an order of magnitude.

In May 2007, the German Ministery of Research and Education (BMBF) has granted our RWTH proposal to build and operate POWTEX, in close collaboration between the groups of Aachen and Jülich. The novel diffractometer, a beautiful example for the recently established "Jülich-Aachen Research Alliance" dubbed JARA, will be realized in the new eastern experimental hall ("Osthalle") of the FRM-2. The first measurements will be available in 2012.

The large German community of solid-state chemists is looking forward to the realization of POWTEX.

Prof. Dr. Richard Dronskowski

Institute of Inorganic Chemistry

RWTH Aachen University

Prof. Dr. Thomas Brückel

Institute for Scattering Methods

Research Center Jülich

|

Impressum und Datenschutzerklärung (Imprint and Privacy Policy) |

Administration |

Print

Impressum und Datenschutzerklärung (Imprint and Privacy Policy) |

Administration |

Print